- Angle Finders & Levels

- Bead Rolling & Rotary Forming

- Books, Videos & Software

- Brakes, Shears & Slip Rolls

- Grinding & Polishing

- Hand Tools

- Ironworkers & Presses

- Machining

- Metal Shaping & Forming

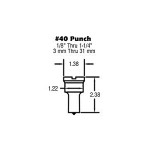

- Punching & Drilling

- Sawing

- Shop Organization

- Tube & Pipe Bending

- Tube Notching & Endforming

- Hole Saw Notchers

- End Mill Notchers

- Abrasive Notchers

- Plasma Tube Notchers

- Punch Type Notchers

- Deburring Hand Tools

- Deburring Machines

- Expander/Swagers

- Bead Form for Tubing

- Centerless Grinding Machines

- Pipemaster Contour Gauges

- Notching Cutters, Dies & Belts

- Endforming and Swaging Dies

- Related Items

- Vises & Clamps

- Welding & Plasma Cutting

- Clamps, Magnets and Fixtures

- Welding Accessories

- Rotary Welding Positioners

- Mobile Carts and Positioners

- Tig Torch Accessories

- BuildPro Jig Tables

- Flextur Fixture Tables

- Powerlift Weld Tables

- Siegmund Metric Series

- Siegmund Imperial Series

- Badass Fabrication Tables

- Beveling Machines

- CNC Plasma Systems

- Exhaust Fabrication Tools

- Related Items

- Fabrication Packages

- Trick-Tools Gear

- Shop by Brand

- 2020 Software

- 3M

- 525 Industries

- AcuAngle

- Anchorlube

- Arc-Zone

- ArcLight Dynamics

- Arcmaster

- Badass Workbench

- Baileigh Industrial

- Bead Form

- Ben Pearson

- Bend Press

- Bend-Tech

- Bessey

- Betenbender

- Beveler USA

- Beverly Shear

- Big Gator Tools

- BuildPro

- Burr King

- C. Cook Enterprises

- CCKL Creator

- Carell

- Carif

- Center-It

- Checkpoint

- Cleko-Loc

- Cleveland Steel Tool

- Combat Abrasives

- Connecticut

- Covell Creative

- Dake

- Digi-Pas

- Drill-Rite

- Dura-loop

- Eagle Bending

- Easy Shrink

- Eckold

- Edwards Mfg. Co

- Ellis

- Ercolina

- Evolution

- EZ Sander

- Fein

- Femi

- Flextur

- Flowdrill

- Fournier Enterprises

- Full-Bore Publishing

- Fulton Metal Works

- Gardner Bully

- Garland

- GEKA

- Glo Tech Inc.

- Good Hand

- Gridlok

- Grit

- HammerFab

- Hardcore Grinders

- HEM Saw

- Hougen

- Huth

- Hyd-Mech

- Hypertherm

- Icengineworks

- Inventive Products

- Irwin

- Jamey Jordan

- Jancy Engineering

- JET

- JMR Manufacturing

- JS Tools

- Kalamazoo Industries

- Kett Tools

- KNKut

- Laguna

- Lancaster

- Lazze

- LevTech

- LowRider

- M-D Building Products

- Markal

- Martin

- Mechammer

- MetalAce

- METALpro

- Midwest

- Mittler Bros

- MK Morse

- Monster

- Multitool

- N.KO Machines

- National

- Nielsen

- NotcHead

- Ogura

- Oregon Products

- Pexto

- Picard

- PipeMaster

- Piranha

- Portaband Pro

- Powerlift

- PowerX

- PrestonEastin

- Pro-Tools

- Project Tool & Die

- ProLine

- Quantum Machinery

- RaceLine

- RadiusMaster

- RAMS

- Roll-In Saw

- Roper Whitney

- Rotabroach

- Roto-Star

- Scantool

- Scotchman

- Sharpie

- Shaviv

- Siegmund

- Slugger

- SmartTool

- Spring Tools

- SPX Power Team

- Starley

- Strong Arm

- Strong Hand Tools

- Swag Off Road

- Tennsmith

- Transfluid

- Trick-Tools

- Triumph Twist Drill

- Trusty-Cook

- Unibit

- Versa-Mount

- Wehrs Machine

- Wilton

- Wixey

- Used & Demo on

- What's New

- Deals

- Best Sellers

- Technical Resources

- Equipment Leasing

- Gift Certificates

- International

- Schools & Government

- Free Catalog

- About Us

- My Account

- View Cart

- Home